Welcome to our guide on the best concrete cutting tools, where we’ll break down everything you need to know to cut through one of the toughest materials with confidence. Choosing the right tool can mean the difference between a clean, precise job and a messy, time-consuming headache. Whether you’re a homeowner taking on a DIY project, a contractor looking for reliable equipment, or someone simply curious about what works best, this article will help you understand the options available, their pros and cons, and how to choose based on your specific needs. From concrete saws and angle grinders to diamond blades and specialty tools, we’ll cover the essentials while also sharing practical safety tips, buying advice, and answers to common questions so you can make smart decisions and get the job done right.

The best concrete cutting tools include concrete saws (handheld and walk-behind) for deep, straight cuts, angle grinders for small or detailed work, core drills for clean holes, and specialty options like concrete chainsaws or wire saws for heavy projects. Pairing these tools with diamond blades ensures faster, cleaner, and safer cuts. Choose your tool based on project size, cut depth, and whether you need precision or power.

Table of Contents

Why Choosing The Right Tool Matters

Cutting concrete is not as simple as grabbing the first tool you find and getting started. The tool you choose plays a direct role in the quality of your work, your safety, and the overall time and cost of the project. Using the wrong tool may seem like a shortcut, but it can quickly lead to bigger problems that make the job harder than it needs to be.

One of the most common risks of using the wrong tool is poor quality cuts. Concrete is tough, and when you attempt to cut it with a tool not designed for the task, you may end up with cracks, chips, or uneven lines. This doesn’t just affect the appearance, it can compromise the strength and stability of the material. A simple project like cutting a slab for a patio or making an opening for pipes can turn into a costly repair job if the wrong tools are used.

Another key factor is wasted materials. When tools fail to make accurate or clean cuts, sections of concrete often need to be redone. This can mean buying more concrete, investing extra time, and putting in double the effort. For larger projects like driveways or foundations, these mistakes can multiply quickly, adding unnecessary expenses.

Safety is also a major concern. Tools that aren’t powerful enough can overheat, break down, or even kick back unexpectedly. Dust exposure becomes worse when blades are not suited for concrete, increasing health risks for your lungs and eyes. Proper concrete cutting tools are designed to control these issues, helping protect both the user and the work environment.

Efficiency should never be overlooked. The right tool doesn’t just make the work safer, it also saves time. A high-quality concrete saw with a diamond blade can cut through a slab smoothly in minutes, while the wrong tool could take hours and still deliver poor results. For professionals, time saved translates to higher productivity. For DIY users, it simply means less frustration and faster project completion.

Main Types Of Concrete Cutting Tools

Concrete cutting requires the right tool for the job. Using the wrong equipment can slow down progress, reduce precision, and even put safety at risk. Below are the main categories of tools, their uses, and the situations where they work best.

Concrete Saws

Concrete saws are among the most common and versatile tools for cutting through slabs, driveways, and large surfaces.

- Handheld cutoff saws: These saws are portable, easy to handle, and effective for smaller cuts or projects where maneuverability is important. The downside is their limited depth capacity, which makes them less suitable for thick concrete slabs.

- Walk-behind saws: Built for heavy-duty work, walk-behind saws can cut much deeper and handle larger projects such as sidewalks, roads, or big floor sections. Their drawback is the weight and reduced mobility, which means they are best used in wide, open spaces.

- When to use each: A handheld cutoff saw is ideal for smaller, precise cuts and repair work, while a walk-behind saw is the right choice when tackling deeper or more demanding cuts on large surfaces.

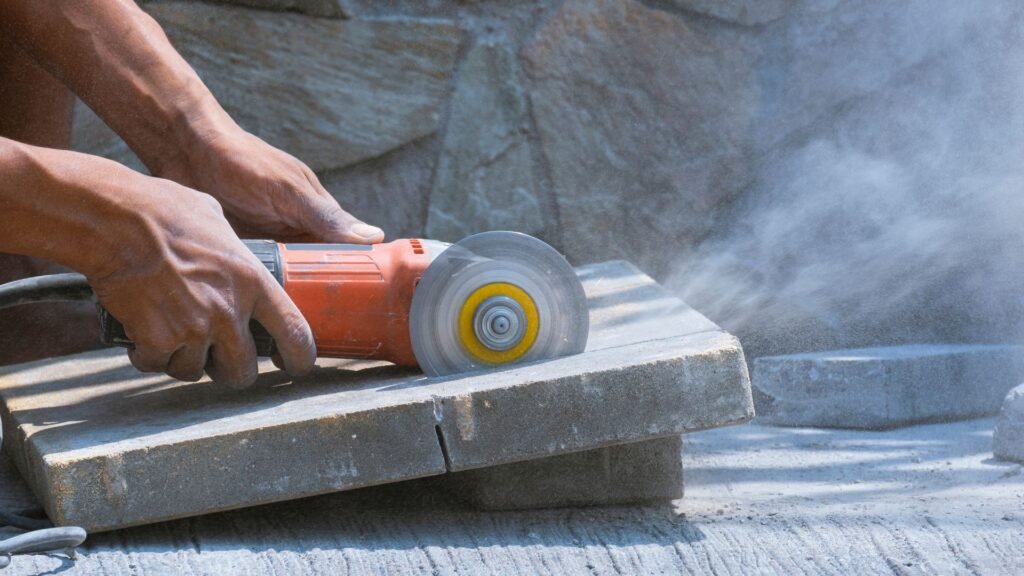

Angle Grinders

Angle grinders are smaller tools often used for detail work, surface grinding, or trimming concrete edges.

- Good for small cuts and detail work: They shine when accuracy matters and you need to shape or smooth edges.

- Best blade types: Fitting an angle grinder with a diamond blade ensures cleaner cuts and better durability.

- Limitations: Angle grinders are not designed for heavy-duty projects or deep cuts. They are better suited for finishing tasks rather than primary cutting jobs.

Core Drills

Core drills are specialized tools designed for making clean, round holes in concrete. They are often used by electricians, plumbers, and contractors who need precise openings for pipes, wires, or utilities.

- Ideal for clean holes: A core drill allows you to create perfectly circular cuts without cracking or damaging the surrounding concrete.

- Difference between handheld and rig-mounted drills: Handheld drills are portable and convenient for smaller jobs, while rig-mounted versions are more stable and suited for larger, deeper holes that require precision.

Jackhammers And Rotary Hammers

These tools are different from saws and grinders because they are built to break concrete rather than slice through it.

- When to break rather than cut: If the goal is demolition or removing sections of concrete instead of shaping it, jackhammers and rotary hammers are the most effective choice.

- Differences in application: A jackhammer is best for large-scale demolition work, while a rotary hammer is smaller and more versatile, making it useful for medium jobs or when drilling into reinforced concrete.

Specialty Tools

Specialty tools are designed for unique cutting needs that go beyond standard projects.

- Concrete chainsaws: These tools function like a traditional chainsaw but are engineered with diamond chains to handle tough concrete. They are excellent for cutting openings with square corners or when working in confined spaces.

- Wire saws: A wire saw uses a wire embedded with diamond beads and is often the only choice for cutting massive or complex structures, such as bridges, large pillars, or heavily reinforced concrete.

These tools are nice, but essential for jobs where standard saws or drills cannot deliver the required precision or power.

Understanding the main types of concrete cutting tools helps you match the right equipment to your project. Whether you need a portable saw for a quick cut, a grinder for finishing edges, or a specialty tool for complex jobs, choosing wisely ensures safer, faster, and cleaner results.

Best Blades And Attachments

When it comes to cutting concrete, the blade or attachment you choose plays a major role in how effective and safe the process will be. Using the wrong blade can slow you down, wear out quickly, or even create safety hazards. Below are the most common options and how to select the right one for your project.

Diamond Blades Vs Abrasive Blades

Diamond blades are the top choice for most concrete cutting projects. They are designed with synthetic diamond crystals on the edge, which provide exceptional durability and precision. These blades cut faster, produce smoother edges, and can handle reinforced concrete with ease. They also last significantly longer, making them more cost-effective over time despite the higher upfront price.

Abrasive blades, on the other hand, are made from composite materials that grind through concrete rather than slice it. While they are cheaper, they wear down quickly and often require frequent replacements. They are best suited for small, occasional projects where precision and longevity are less critical.

Wet Cutting Vs Dry Cutting

Wet cutting uses water to cool the blade, minimize friction, and control airborne dust. This method improves blade life, reduces the risk of overheating, and creates a safer environment by limiting harmful silica dust. It is especially recommended for larger jobs or indoor projects where dust management is important.

Dry cutting is more convenient for smaller tasks since it does not require a water source. However, it generates significant amounts of dust, which can be hazardous if proper protection is not used. Dry cutting also requires frequent pauses to let the blade cool, making it less efficient for large-scale work.

How To Choose Based On Project Scale

The right choice depends on the size and scope of your project. For small DIY tasks such as trimming concrete blocks or making shallow cuts, an abrasive blade or dry-cutting diamond blade may be sufficient. For medium to large projects like driveways, patios, or thick slabs, a diamond blade with wet cutting will deliver cleaner results, longer blade life, and a safer experience. Contractors and frequent users should always invest in high-quality diamond blades and use wet cutting whenever possible to ensure efficiency and safety.

The right blade and cutting method can save time, improve safety, and deliver a professional finish. By matching the blade type and cutting style to your project scale, you’ll not only protect your equipment but also achieve smoother, cleaner cuts with less effort.

Safety Tips You Shouldn’t Ignore

Concrete cutting is tough work, and safety should always be your top priority. Using the right protective gear, managing dust, and keeping your tools in good condition will not only protect you but also make the entire process smoother and more efficient.

Protective Gear: Gloves, Goggles, Masks, And Ear Protection

Before you start cutting, make sure you’re properly equipped. Heavy-duty gloves protect your hands from sharp edges, vibrations, and accidental slips. Safety goggles are essential for shielding your eyes from flying fragments of concrete, while a dust mask or respirator prevents harmful particles from entering your lungs. Since concrete cutting tools generate high noise levels, ear protection such as earmuffs or plugs should always be worn to reduce the risk of long-term hearing damage.

Handling Dust And Debris

Concrete dust is more than just a nuisance, it can be hazardous to your health. Silica dust, in particular, can lead to serious respiratory issues if inhaled over time. To minimize this risk, consider wet cutting whenever possible, as water helps control dust at the source. If wet cutting is not an option, work in a well-ventilated area and use vacuums or dust extractors designed for concrete dust. Always clear debris promptly to keep your work area safe and avoid trip hazards.

Importance Of Proper Tool Maintenance

Maintaining your tools is just as important as using them correctly. Dull blades or poorly maintained machines increase the risk of accidents and make cutting far more difficult. Regularly inspect blades for wear, check that guards are secure, and ensure all moving parts are lubricated and functioning properly. A well-maintained tool not only lasts longer but also delivers cleaner cuts with less effort, saving you both time and frustration.

By paying attention to protective gear, dust management, and tool care, you can complete concrete cutting tasks with greater confidence and safety. Taking these steps will help you stay protected while achieving the best possible results.

How To Choose The Best Tool For Your Project

Choosing the right concrete cutting tool can feel overwhelming, especially with so many options available. The key is to match the tool to your specific project needs. By considering a few important factors, you’ll avoid wasted time, reduce safety risks, and achieve a cleaner, more accurate result.

- Project size: Start by looking at how big your job is. If you’re cutting a small slab or handling detail work around the edges, a handheld saw or angle grinder will usually be enough. For bigger projects, like cutting through a driveway or sidewalk, a walk-behind saw is more practical since it offers deeper cuts and better efficiency.

- Budget: Tools can get expensive, especially professional-grade equipment. Think about how often you’ll use the tool. If it’s a one-time job, renting is often the smarter choice. For contractors or homeowners tackling multiple projects, buying might save money long term.

- Depth of cut: Each tool has limitations. Handheld saws can handle a few inches, while walk-behind models go much deeper. Always measure the thickness of the concrete you’re cutting so you don’t pick a tool that can’t handle the job.

- Precision needed: Some projects call for clean, smooth edges, while others just need the concrete broken up. If you’re drilling holes for plumbing or wiring, a core drill offers precision. For demolition, a jackhammer or rotary hammer is a better match.

- Questions to guide your decision include: Am I cutting a small slab or a driveway? Do I need portability or power? Thinking through these will quickly point you in the right direction.

- Buy vs rent: If you’ll only cut concrete once, renting from a local equipment supplier is the most cost-effective approach. If you’re a professional or plan to take on future projects, investing in a high-quality saw, grinder, or drill may pay off over time.

Making the right choice comes down to matching the tool to your project’s scale, budget, and level of precision. By weighing these factors carefully, you’ll save both money and effort while ensuring a safer and cleaner cut.

Top Brands And Where To Buy

When it comes to choosing the best concrete cutting tools, the brand you select plays a major role in the performance and durability of your equipment. Reliable brands not only ensure precise cuts but also provide safety features and long-lasting value. Here are some of the most trusted names you will encounter when shopping for concrete cutting tools:

- Husqvarna: Known for professional-grade concrete saws, chainsaws, and specialty equipment. Husqvarna tools are often the go-to choice for contractors who need powerful machines that can withstand demanding projects.

- Bosch: A popular option for both professionals and DIY users, Bosch offers versatile tools such as angle grinders and drills. Their balance between quality and price makes them a solid mid-range choice.

- Makita: Widely respected for producing durable and ergonomic tools, Makita is often chosen for projects that require reliability and long hours of operation. Their power tools are designed with user comfort in mind.

- DeWalt: Trusted for affordability and accessibility, DeWalt tools are commonly used in small to medium projects. They are a great entry point for beginners or homeowners who want effective results without spending heavily.

Pro-Grade Vs Budget-Friendly Options

Pro-grade tools from brands like Husqvarna and Makita are designed for frequent use, heavy workloads, and maximum precision. They are built to last and often come with advanced features that make them ideal for contractors and professionals. Budget-friendly options, such as those from DeWalt or certain Bosch models, are more affordable but still deliver dependable results for smaller projects or occasional use. While budget tools may not last as long under extreme use, they are perfect for homeowners or DIY enthusiasts who only need them a few times a year.

Online Vs Local Stores

When deciding where to buy concrete cutting tools, you can choose between online platforms and local hardware stores. Online stores provide convenience, a wide selection, and the ability to compare prices quickly. You can also read customer reviews before making a purchase. On the other hand, local stores offer expert advice and hands-on experience. You can test the tools, ask specific questions, and get guidance on the right equipment for your project. For many buyers, a combination works best, researching online for options and then visiting a store to finalize the purchase.

Choosing the right brand and place to buy depends on your budget, project scale, and personal preference. Whether you decide to invest in pro-grade equipment or stick with budget-friendly options, always aim for trusted brands that deliver consistent quality.

Ready to tackle your next project with confidence? Discover more expert tips, trusted guides, and the right tools to get the job done. Visit our homepage and start building smarter today.

FAQs: About Best Concrete Cutting Tools

What are the best tools for cutting concrete?

The best tools include concrete saws, angle grinders, core drills, jackhammers, and specialty options like concrete chainsaws or wire saws. Each tool works best for different project sizes and requirements.

Can I cut concrete with a regular circular saw?

You can use a circular saw with a diamond blade for shallow cuts, but it’s not designed for heavy-duty concrete cutting. For deeper or larger jobs, a concrete saw or walk-behind saw is more effective.

Do I need a diamond blade to cut concrete?

Yes, diamond blades are the preferred choice because they provide cleaner, faster cuts and last longer than abrasive blades. They’re essential for both professional and DIY projects.

What’s the difference between wet cutting and dry cutting?

Wet cutting uses water to cool the blade, reduce dust, and extend blade life. Dry cutting is convenient for smaller jobs but creates more dust and requires frequent breaks to prevent overheating.

When should I use a core drill instead of a saw?

A core drill is best when you need precise, circular openings for plumbing, wiring, or utility lines. Saws are better for straight cuts, slab work, or larger sections.

Is it better to rent or buy concrete cutting tools?

If you only need the tool for a single project, renting is cost-effective. For frequent or professional use, investing in high-quality tools may save money long term.

What safety gear do I need when cutting concrete?

Always wear safety goggles, gloves, a dust mask or respirator, ear protection, and sturdy clothing. Proper ventilation and dust control are also important when working indoors.

How deep can a concrete saw cut?

Handheld saws usually cut 4–6 inches deep, while walk-behind saws can reach up to 14 inches depending on the blade size and machine power.

Can beginners safely use concrete cutting tools?

Yes, beginners can handle smaller tools like angle grinders or handheld saws with proper safety precautions. Larger equipment, like walk-behind saws, is better for experienced users or supervised operation.

What brands make the best concrete cutting tools?

Trusted brands include Husqvarna, Bosch, Makita, and DeWalt. These companies offer reliable tools with options suited for both professionals and DIY users.

Conclusion

The right concrete cutting tool makes every project safer, faster, and cleaner because it allows you to achieve accurate results without wasting time or materials. When choosing equipment, take a moment to assess your project needs—think about the size of the job, the depth of cuts required, and whether you need portability or heavy-duty power. By matching the tool to the task, you avoid common mistakes such as uneven cuts or unnecessary wear on blades. For beginners or anyone unsure about investing, renting or testing tools first is a smart way to find out what works best before committing to a purchase. With the right approach, you’ll save money, work more efficiently, and complete your project with confidence.